Note: Please see my Version 3.2 post for the current design: Link

System Description:

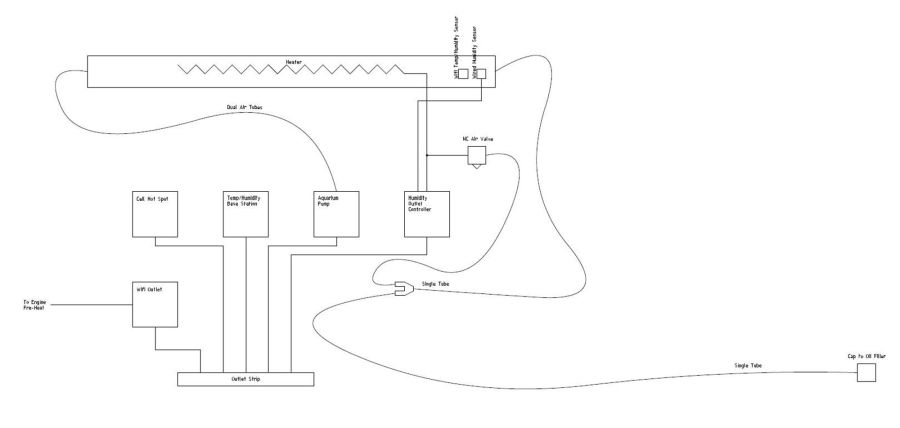

I decided to build a system that could be remotely controlled via cellular connected monitoring system that would allow me to pre-heat my engine from home and for a self contained engine dehydration system that can also be monitored from my phone. Basically there are three parts to the system: Cellular/Wifi backbone, Remote outlet to control the engine preheat, and the Engine dehydration system that can remotely monitored.

Engine Dehumidifier:

The system pumps dry air through the engine (the air is dried with Silica Gel Beads Desiccants), the humidity is monitored and when the desiccants need to be recharged automatically using a heater (after disconnecting the air to the engine), remote monitoring of the system (temperature and humidity).

Assembly of the drying vessel:

From the left end:

1. A mess screen was wrapped around a PVC pipe cap that had holes drilled through the end

2. The humidity controlled outlet sensor and the Wifi remote temperature/humidity sensor were inserted into the pipe and sealed with the end cap that included the dry air tubing to the engine

From the right end:

1. The resistor heater assembly was inserted and the wires attached using wire nuts (wire nuts prevent scouring pad from contacting wires)

2. The vessel was filled to the top of the resistor heater assembly with silica beads

3. A stainless steel scouring pad was inserted

4. The end cap that included the two incoming air source tubes (with bubblers installed on the inside)

Assembly of the enclosure:

Humidity Controller IHC200 Settings:

HS – 20.0

Hd – 1.0

dd – 1.0

AH – 99.0

AL – 0.0

Pt – 1

CA – 0.0

Interested in how I got to Version 3.2? You can checkout the previous versions:

Version 3.2: Change to PVC piping to insert a plug with a small hole on the sensor/dry air side Link

Version 3.1: Change to custom humidity control programming: Link

Version 3.0: Change to custom humidity control PCB: Link

Version 2.0 Change of heating method: Link

Version 1.0: Link

Thanks for the design, it looks great! I do have a few questions about the setup, any amplifying information would be greatly appreciated:

1. On what I believe is the output / dry air end there are multiple holes in the cap, what is the purpose of this? I would think a dry air tube to the engine without loss would be the preference?

2. What is the purpose of the stainless steel scouring pad? Does it act as a filter?

3. What is the purpose of the NC Air valve?

Kind Regards,

Jake

1. The output end to the engine only has a single tube (it is not shown) the cap with two tubes and the aquarium bubblers is the incoming air. The cap with multiple holes (along with the wire mesh screen) is placed inverted into the PVC pipe to keep the silica beads in place and to create a pocket for the humidity and temperature sensors

2. The stainless steel scouring pad is meant to act as a spacer for the aquarium bubblers

3. NC Air valve is used to allow the moist air when regenerating (heating the silica beads) to escape without pushing that air through the engine