Note: Please see my Version 3.2 post for the current design: Link

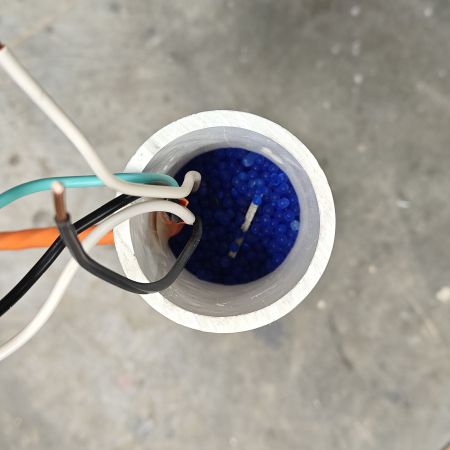

Whew, what a journey and learning process in figuring out the recharging system for the silica beads. So much trial and error of drying mechanisms – note to self, do NOT install a thermal switch when testing resistor combinations – it seems the time consuming process of swapping resistors and wiring configurations of the resistors is a waste of time when the thermal switch does it’s job… Lesson learned. Ultimately after many hours of testing and experimenting I was most happy with 3 sets of three 330 ohm resistors in series (nine resistors total). This results in the 175 degrees (f) on the hottest spot of the outside of the PVC tube.

Assembly of the Silica Bead and Heater vessel:

Tested recharge methods:

A number of methods were tested to recharge the Silica beads, more information can be found here: Link

Interested in how I got to Version 3.2? You can checkout the previous versions:

Version 3.2: Change to PVC piping to insert a plug with a small hole on the sensor/dry air side Link

Version 3.1: Change to custom humidity control programming: Link

Version 3.0: Change to custom humidity control PCB: Link

Version 2.0 Change of heating method: Link

Version 1.0: Link

No Comments