UPDATE August 1, 2016!!! – I removed the InterVolt Programmable Voltage Relay, see the new post for more information: Update

With the boat wiring mapped out I felt comfortable stripping out the old batteries and wires. Figuring out where to mount all of the new equipment was a game of Tetris. Ultimately I had to adjust the position of the Xantrex inverter and retractable TV controller to make space in between them for the Victron solar controller.

Secured Xantrex inverter and Victron solar inverter

This boat has a lot of power cables… I had to make cables to run from each battery to the InterVolt Programmable Voltage Relay (low voltage cut off device). Paralleling cables for the four 200Ah batteries to the second set of 200Ah batteries. Crimp new ends on the ground cables that connect to the M12 bolts on the house batteries and M6 on the new lithium starter batteries. Also the cables connecting power to the boat need M8 ends for the InterVolt PVR. I was very lucky and my boat neighbor Rick had a professional crimp tool (and glue filled heatshrink tubing) which saved me buying an expensive tool for the project. Rick was a great resource, he has over 40 years of commercial boat ownership and he even built a sailboat from scratch 15 years ago.

Various cables that were needed, using 1/0 gauge wire

I also replaced the solar cables (6 gauge); one went from the breaker to the solar controller, and the other went from the solar controller to the boat ground bus.

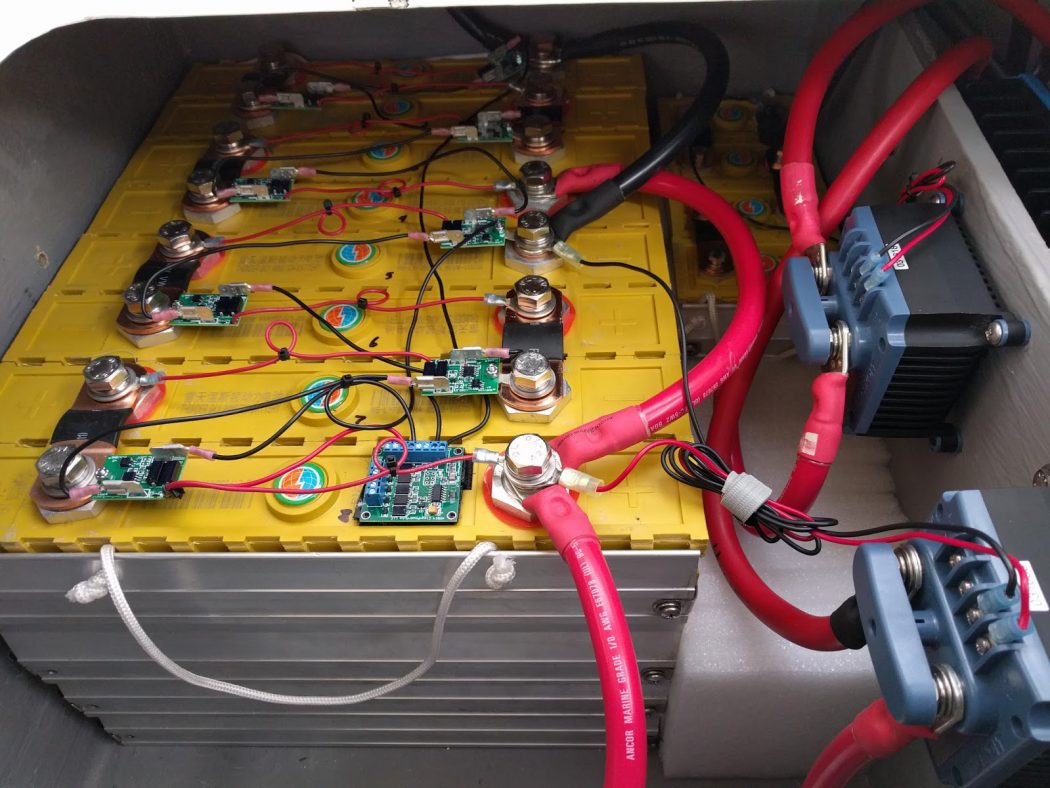

I went with HousePower BMS from CleanPowerAuto and the individual MiniBMS Cell Modules on each cell. For the Winston 200ah batteries it was the “D” sized and 3.8V versions. For the Starter battery it was the “A” sized.

There were a lot of wires to build, since there is a loop made from cell module to cell module, that starts and stops at the HousePower BMS main board. I also had to build power cables for the HousePower BMS.

Cables made, it was time to pull the old lead acid house batteries. 160 pounds of joy came out with a little help from Robby, another boat neighbor.

Notice the chipped fiberglass, ugh

A whole mess of wiring is required to safely maintain and monitor the health of the lithium batteries, both house and starter. I used closed cell foam that the batteries were shipped with to separate the house and starter batteries and to fill the gap between the shorter starter battery pack and the house battery pack. Holes were drilled for the thick aluminum plate that secures the batteries from shifting.

I waited until the evening to connect the solar panels to the inverter. Even then I still covered the panels with a tarp to reduce the current when making the final connections. Now just have to wait until the morning to see how much energy we can capture from the sun!

No Comments