Success!

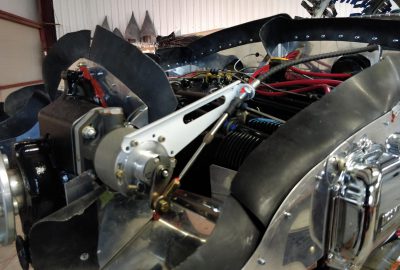

With four hours until the inspector arrived it was hustle time to knock off the last few items. First up was installing the lighting and Plexiglas in the right wing tip. After making a few passes on englarging the opening the landing and taxi lights slid right in and from there is was easy going. The wing root fairings were…