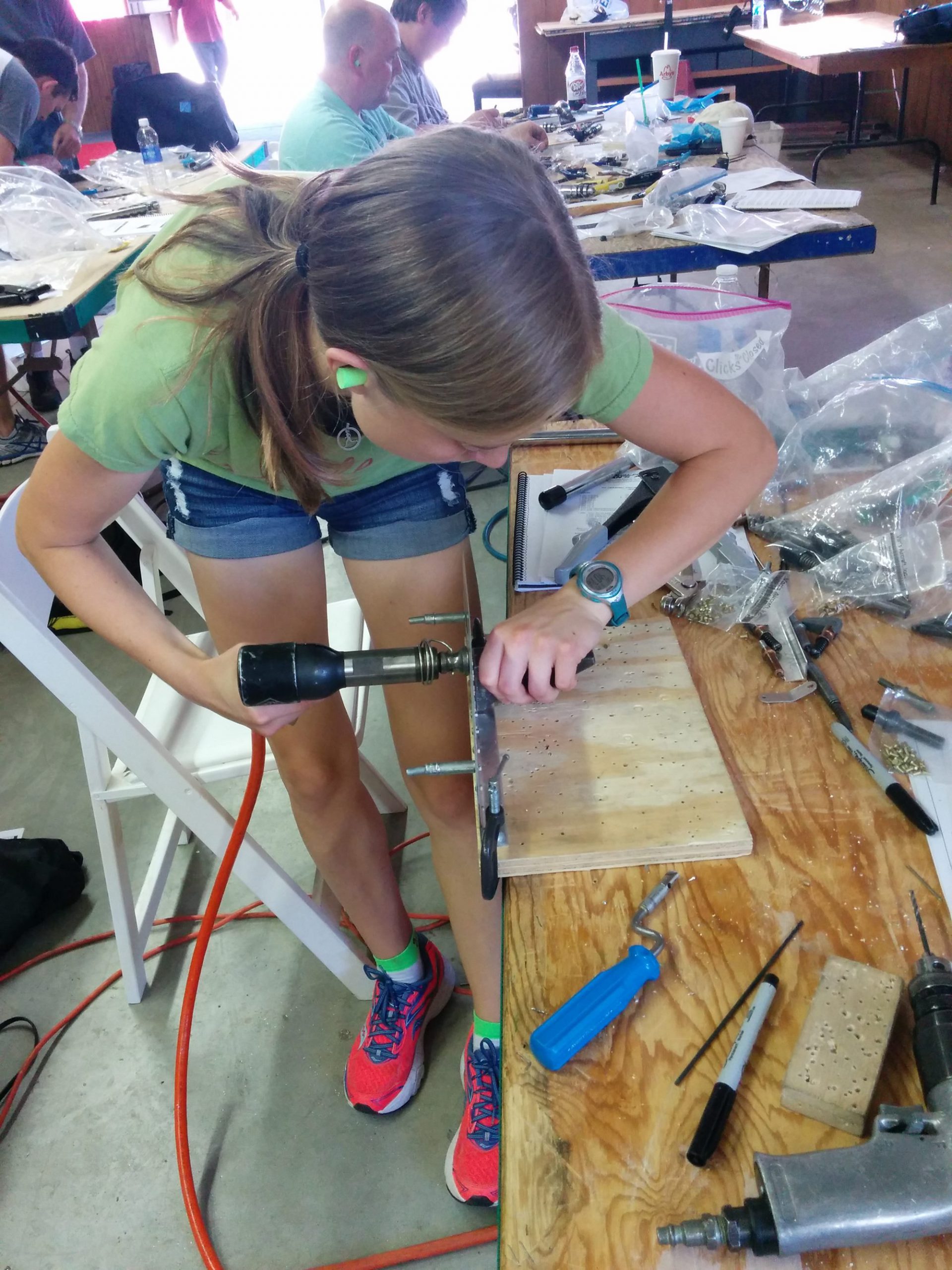

I am someone who always needs to have a project in my life. With my time with SV Strikhedonia coming to an end, ideas had been bouncing around in my head. For years the idea of building an airplane popped up but the commitment and idea of pounding tens of thousands of rivets after drilling, deburring, and dimpling seemed daunting. Hell, Anna and I even took a class at Oshkosh in in 2015. That was more to understand the process than with the expectation of actually building a plane…

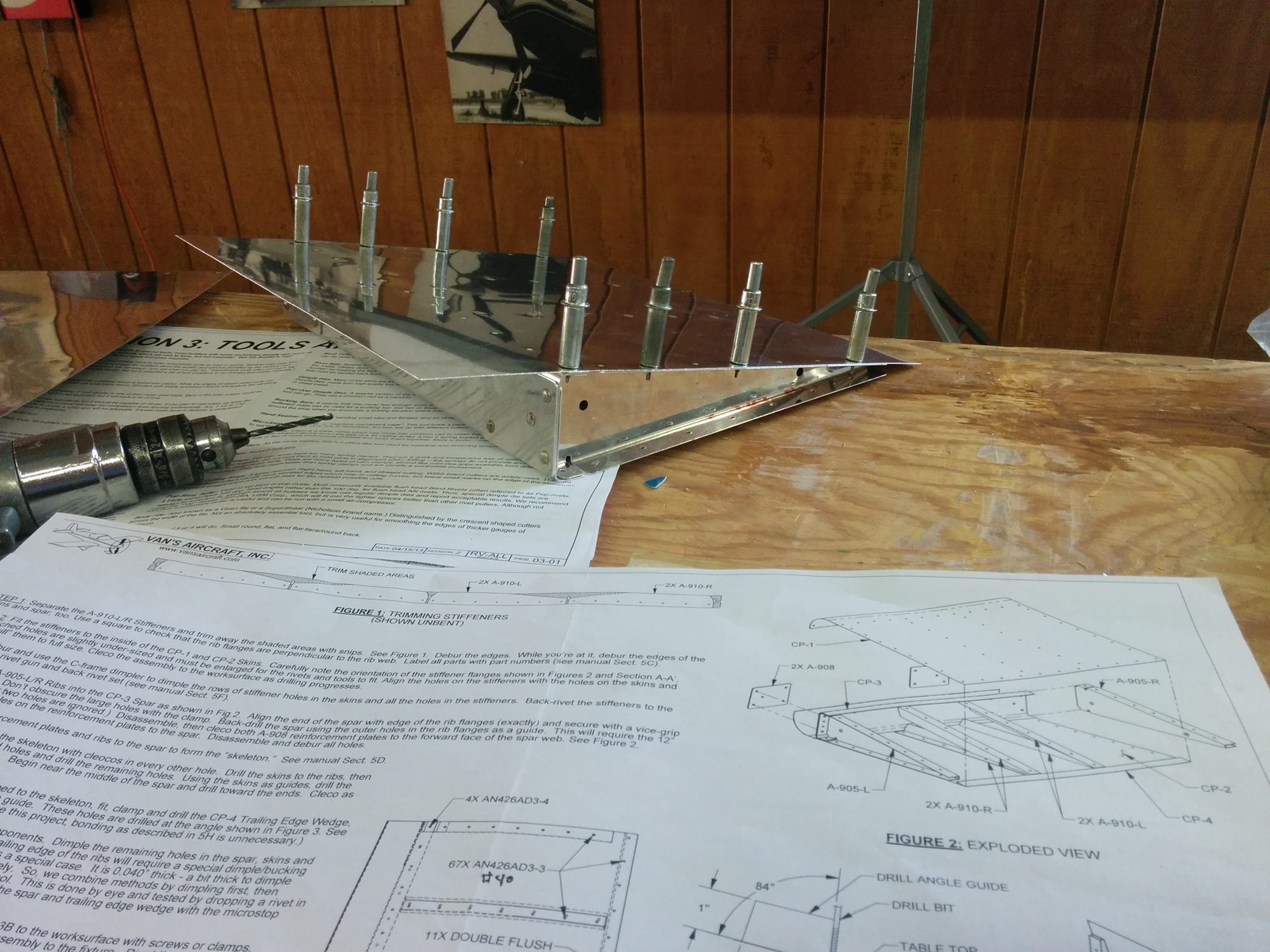

Last summer it crossed my mind again and this time I let my mind drift down that rabbit hole. And what a hole it was. Backing up a bit, my friend and former flight instructor pitched buying an used Van’s RV aircraft a few years ago, but with Strikhedonia my answer was that I could only manage one major toy at a time. Circling back last summer I revisited the Van’s RV kit planes and quickly focused on the RV-10 which is a four person, single engine, fixed gear aircraft that cruises at about 200mph the same as my beloved Piper Aztec (six person, twin engine) that I sold after starting my business back in 2005. For those unfamiliar, Van’s Aircraft currently has nine models (the RV-10 is the largest) and over 10,600 aircraft have been completed and flown. Wow! As a point of reference, the closest competitor to the RV-10 is a production aircraft, by Cirrus and their SR aircraft numbers about 7,000. The Cirrus would cost about 3X the RV-10 and with a bigger engine to go the same speed burn more fuel = higher operating costs. Oh and speaking of operating cost, by building it myself I am certified by the FAA to perform the annual Condition Inspection, saving a few thousand dollars a year.

Decision made, late last summer it was time to begin the research phase. There are many aftermarket options and improvements, filtering through the options was daunting. VAF forum, spreadsheets, bookmarks, and datasheets were poured over. The “customization” is part of the fun but damn is it time consuming and that is before pounding a single rivet. One final major decision was to find a way to accelerate the build process. Most builders end up putting in 2,500 to 3,000 man hours spread out over a period of years. I’m not that patient and plan to work full time throughout the build process but even then it would be at best a few years. More research and I stumbled on a father/son team in Colorado Springs. They have built/helped finish hundreds of RV aircraft. I decided to leverage their knowledge (saving me time pouring over the excellent build instructions/drawings) to help finish in less than a year. I talked with Loyd at RV Builder a few times and made the call that these are the people I want to spend 40+ hour weeks working with to build my airplane. Their current projects would be completed late summer 2020 which lined up well with my plans so the deal was done.

I’m now in the middle of project planning to keep the build on schedule and prepping for the experience!

No Comments