I finished up the baggage area today. This included riveting the diagonal cover I had to drill out the rivets yesterday due to other rivets I had forgotten to pound… I fabricated a new steel baggage door lever, since the one that was included was 90 degrees off from what I needed. But on the plus side it provided me with a good template. Then I shaped the outside edge of the baggage area to make for a smooth transition between the fuselage and the door.

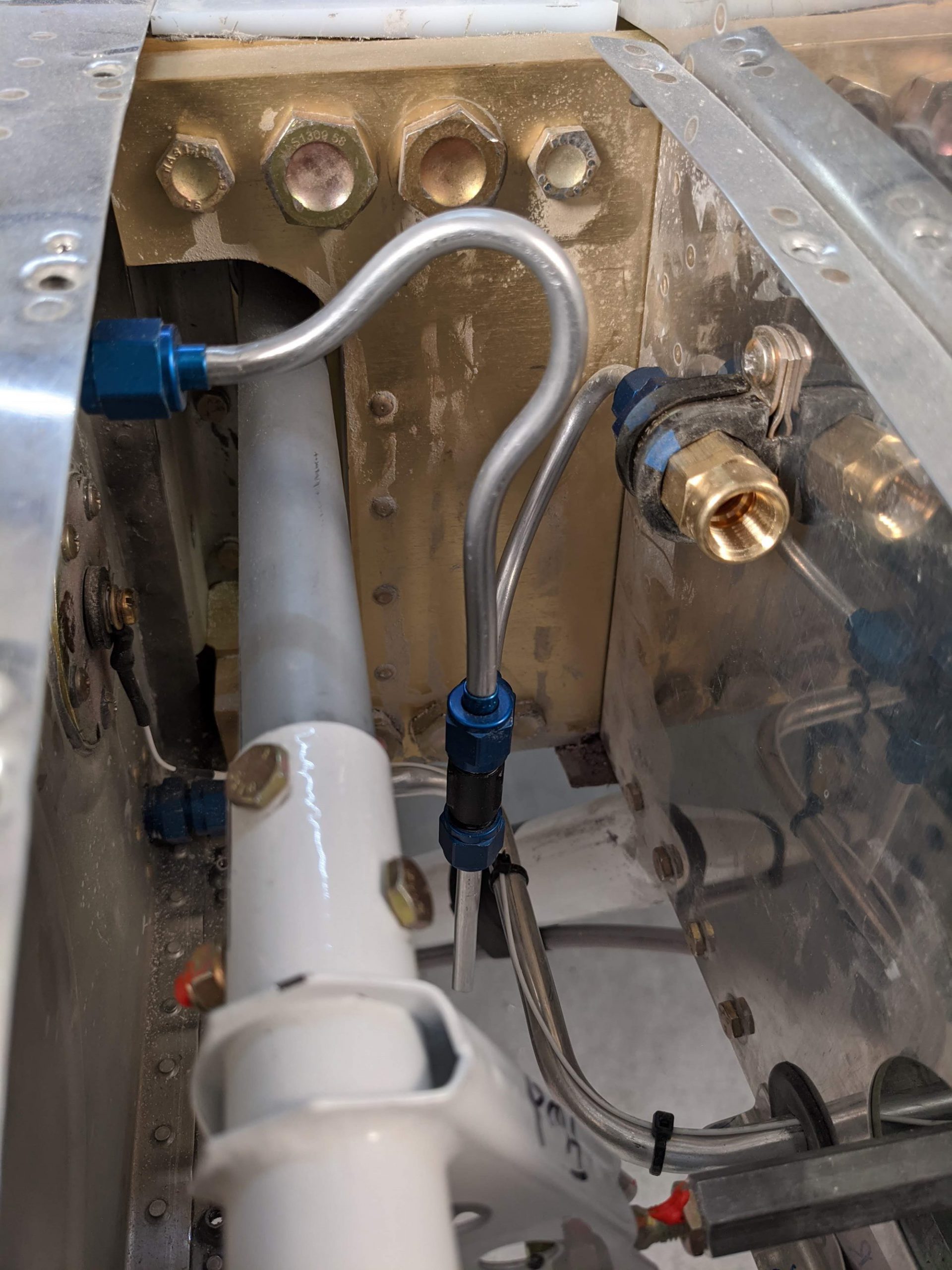

The day started with finishing up the fabrication of the right side fuel vent line. Then checking both for clearance on the wing root fairings. All good.

A big project for the day was torquing all of the hardware in the wings for the flaps and ailerons. As I did each nut/bolt I would torque seal it to provide a double check that I didn’t miss anything. Then it was time to check the travel of the control surfaces. Van’s provided min/max values and I am happy to say that all surfaces are near the maximum (more control force available) limits.

Back to the baggage area, I fabricated the delrin blocks that provide wear resistance for the rear shoulder harness seat belts. This took a bit of time as there was drilling and slot making. Followed by riveting on the delrin pieces after getting all the parts aligned. Then as I went to install the rear bulkheads I realized that the rear vent scat tube was interfering with the seat belt cables. Damn. So I rerouted the scat tubes and it was all good. Then I could finally put in the gazillon screws that hold the rear bulkhead in place. CHECK!

No Comments