My hanger neighbor sold his Husky and while the new owners were poking around I noticed his Minimax tug sitting in the corner. I asked him if was for sale and he explained that it was gifted to him when I got the hanger but it made a terrible grinding sound and didn’t work. And I was free to have it. Score!

Two issues to resolve, the grinding noise and that the spread between the two attach points were way too small for my RV-10. Well that and some rust and a couple other clean up things. I lugged it home and proceeded to disassemble it. It wasn’t long before I realized the grinding was simple to fix. Score number 1! I stripped off the rusted parts, sanded, wire brushed, and painted them with cold galvanizing paint. Score number 2! That left the issue of the spacing of the attach points. After disassembly I decided that fabricating an adapter plate would be the best solution.

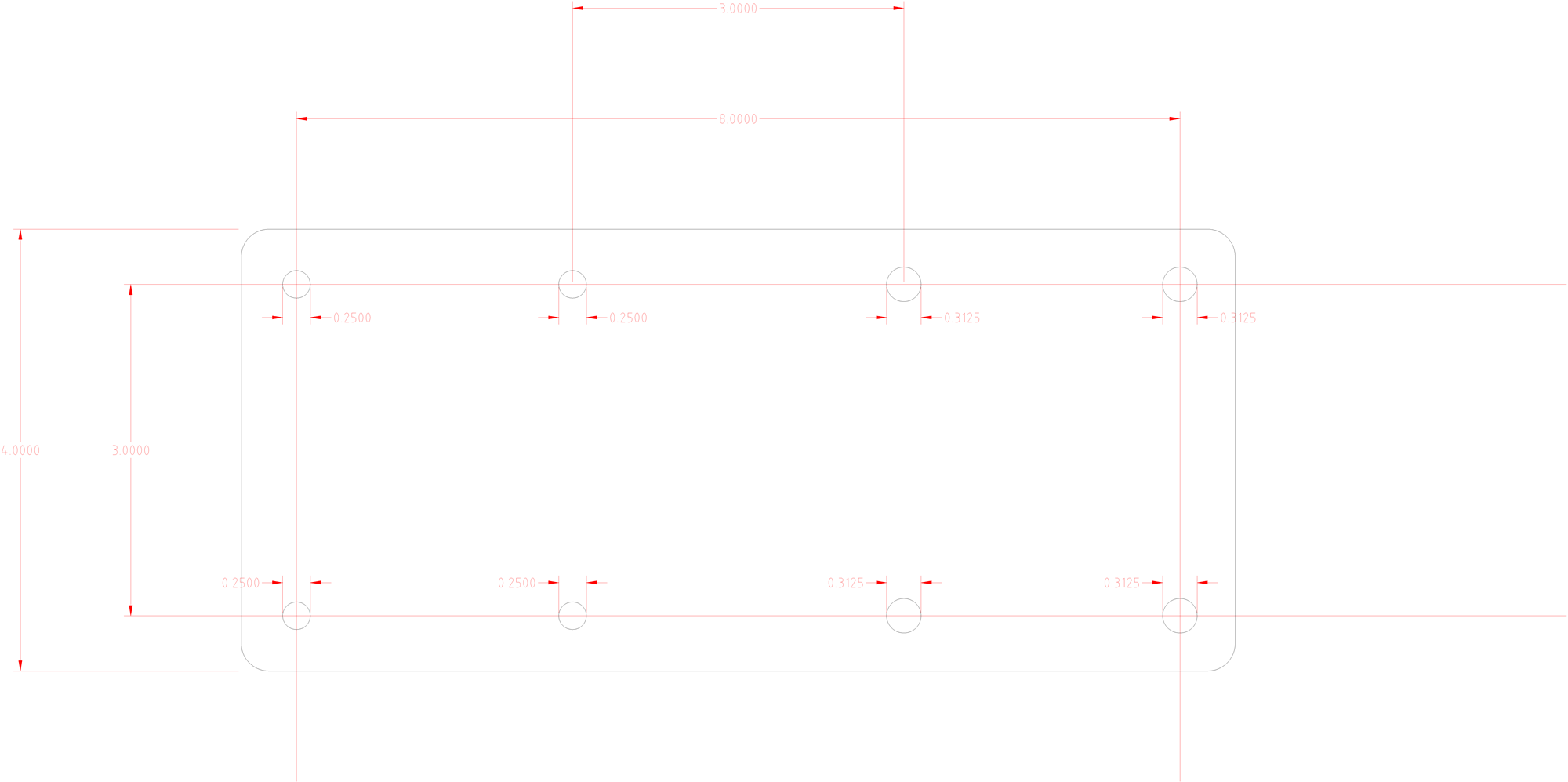

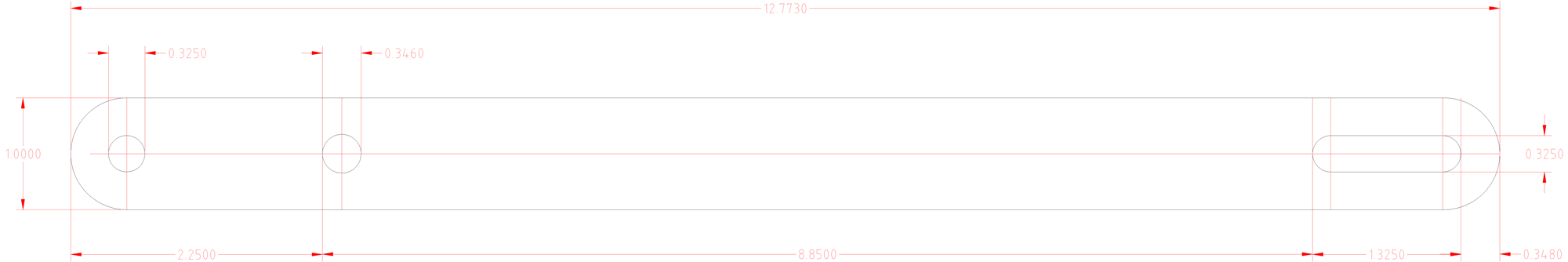

I took dimensions from the tug and then got to drawing up parts on the computer. Numbers double checked, I ordered the adapter plate and the new wider locking handle in mild steel with zinc plating. Once the parts came in, it wasn’t long to have everything bolted together and ready for a test run.

With a few hours of work and $75 I now have a $2,000 tug. Huge score!

No Comments