The ignition cables are now better organized with spacers between to ensure no cross firing. Got the screws installed in the tail fairing, which turned into more work than I expected. Well there were two nutplates involved… Before the window installed I needed to get the sunvisors mounted. With the doors on I could find the best location and then drilled the mounting hole. I was concerned that over time it would be too much stress so before screwing it down I surrounded the sunvisor mounts with flox. Queue bring on more sanding…

With a warm day coming it was go time for the windows. Rough sanding of the window frame and windows was checked off the list. Also the rough clip placement (holds windows while Lord adhesive sets) was figured out. And I finally got around to drilling the holes for Alt Air/Oil Cooler Bowden cables, probably install them over the weekend.

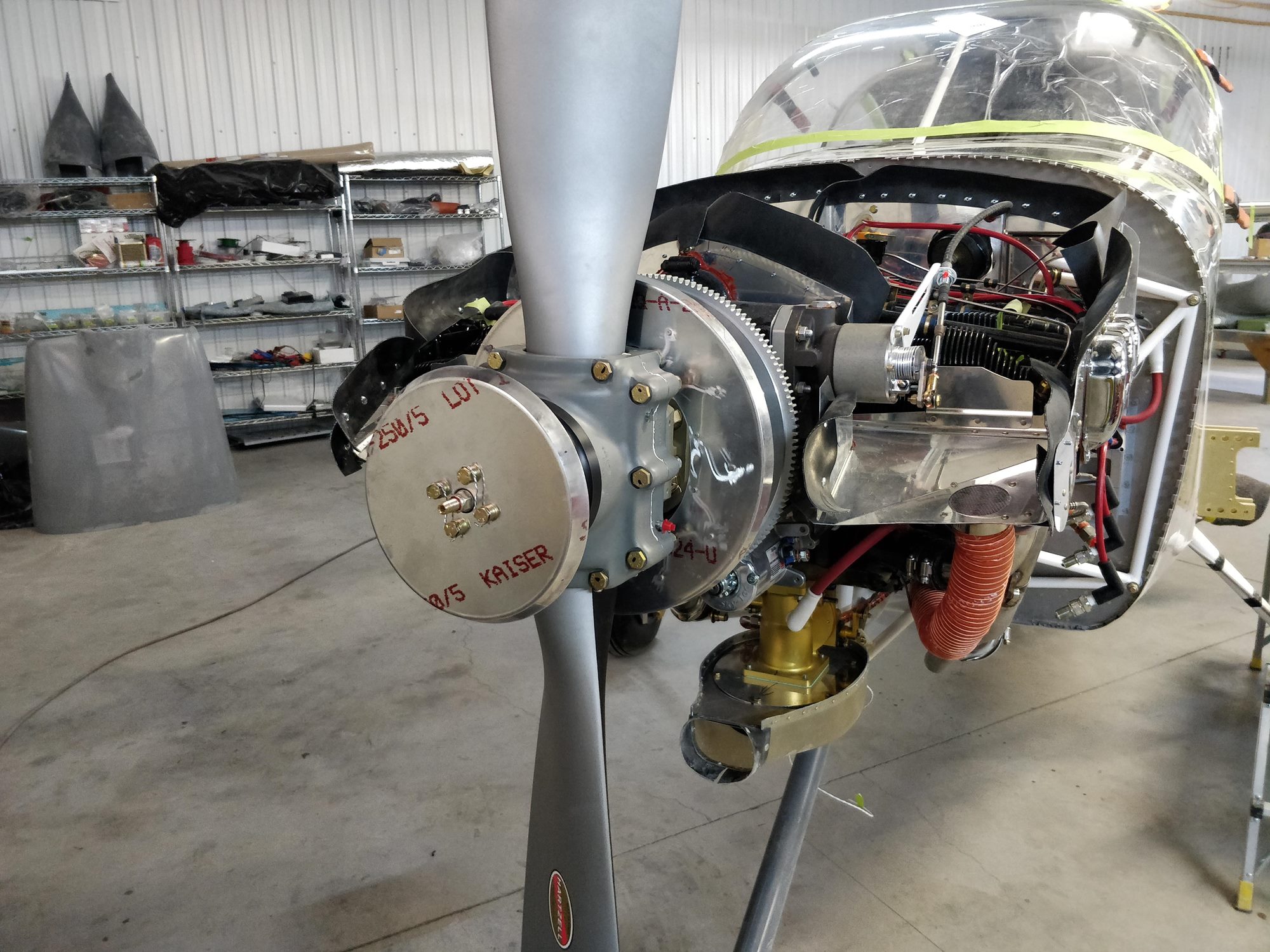

The lower cowling air intake needed a bit of an adjustment to get a good alignment. That involved more flox. For an aluminum plane there sure is a lot of epoxy work… Also added front bulkhead to prop spinner so the engine items is winding down, finally.

Last project for the day was the rear seat and baggage floors install. But not before adding spiral wrap to electrical/antenna cables and installing the steps – which were promptly wrapped with a blanket to protect against one’s shins.

No Comments